Companies that use forklifts are aware of their overall advantages, but they may not be aware of the numerous advantages of a camera system for forklift trucks. Forklifts are important for ensuring that the production chain’s operations run smoothly. They transport goods more quickly and easily to their appropriate destinations.

A lift truck, on the other hand, is used for more than just warehouse maneuvering. To ensure that there are no mishaps or injuries, the operators and all parties involved must put in a great deal of effort.

The good news is that a forklift camera system will make operations run more smoothly and efficiently.

What is a Forklift Camera System?

A typical forklift camera system(Wired or Wireless) comes with 1-2 cameras and monitor. Through the monitor, the operator will be able to see all that is going on in the forklift.

The video from the cameras is shown on the screen, anything you see on the monitor is updated in real time.

Camera Placement

Fork View – You can see if the fork is placed correctly on the monitor with a camera mounted on the inside of the right-hand fork. This makes it easier to avoid inserting the forks wrongly and increases protection when picking up or putting down pallets.

On Fork Carriage – The camera is mounted on the fork carriage or on the mast cross-beam of the innermost mast section, giving the driver a clear view of the forks or other front-end attachments through the monitor.

This enables the driver to maneuver the truck into the best possible position to pick up or lay down goods correctly on the first try, reducing the risk of injury and accidents.

Rear View – As it indicates, camera would be placed at back of a lift truck. When reversing, you’ll have a clear view of the work area at the back of the forklift and be able to drive more safely.

This prevents forklift, warehouse, products, and people from being damaged. When reverse gear is engaged, the monitor in the cab automatically turns to the rear view. You can also choose whether to operate the machine automatically or manually.

So, how does a forklift safety camera system affect a company’s bottom line? Yes, it certainly does. Regardless of the size or nature of your company, forklift operators will benefit greatly from such a camera system.

1. Increases the Safety of Pedestrians

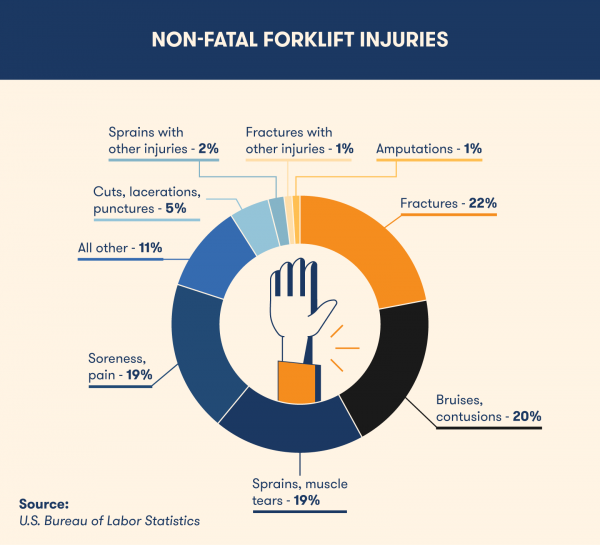

In fact, according to the most recent data from the United States Bureau of Labor Statistics (BLS), nearly 8,000 forklift-related injuries occurred in 2018, an increase of about 6% over the previous year.

The industry also has widely disparate job patterns across the United States, all of which point to a shifting environment for heavy machinery operators.

A forklift can smash pedestrians, cause them to fall from the machine, or cause them to become stuck. Of course, the majority of these mishaps occur due to the operator’s lack of visibility of the surrounding area. It’s possible that the material they’re carrying is too big, obstructing the operator’s vision.

This problem can be solved with a forklift camera system. With the help of cameras, forklift operators can drive around the premises safely. They can also check to see if someone is traveling in the same direction as them and take life-saving measures if necessary.

Overall, the cameras improve pedestrian safety by reducing the number of deaths and accidents caused by forklifts. Employees may be the victims of pedestrian collisions, and such incidents may have a negative impact on their health and well-being.

2. Reduced Product Damage Rates

When products are transported by forklifts, they can be destroyed. While this may seem to be a minor concern to others, it has far-reaching implications for a company’s profitability. Assume that the commodity has gone through many stages of processing, some of which are very costly and time-consuming.

A forklift may harm the product after it is ready for shipment or while it is being transported on a forklift. Such an occurrence would undoubtedly cause you to restart the process from the beginning. As a result, there will be additional costs and delays.

You can protect yourself from such harm with a forklift camera monitor solution. The operator will be able to see the alignment of the product on the forklift in addition to having a good view of the direction they are going to take.

They would be extra careful when maneuvering around as a result of this. They will prevent potentially dangerous conditions and ensure that the goods maintain their original consistency.

3. Blind Spots Reduced or Removed

A forklift operator would be able to detect and avoid potential safety problems that may exist in the forklift’s inherent blind spots with the aid of the camera system. This happens when the camera is placed in a location where their vision would be blurred if they didn’t have the camera installed.

This function is especially useful when the forklift is leaving a trailer or coming down a long aisle. The front of the forklift is another area to consider for camera placement. The explanation for this is the operator’s poor visibility when navigating the forklift through the mast.

Depending on the type of mast you have, such as a three-stage or four-stage mast, the forklift operator’s line of sight can be significantly reduced. The installation of a camera on the forklift’s overhead guard is one way to improve the operator’s line of sight.

4. Boost Your Productivity

Every company strives to increase its productivity as much as possible. Only if all of the structures are in good working order will this be accomplished.

Both of the employees should be in good health (both physically and mentally), and the machines should be in good working order, among other things. This can be accomplished with the aid of a forklift camera system.

Understanding the proximity of their forklift to other forklifts, pedestrians, and other possible hazards in their work area by visual observation will greatly assist in the safe operation of a forklift. All of this should make it easier for the forklift operator to transport products and materials safely.

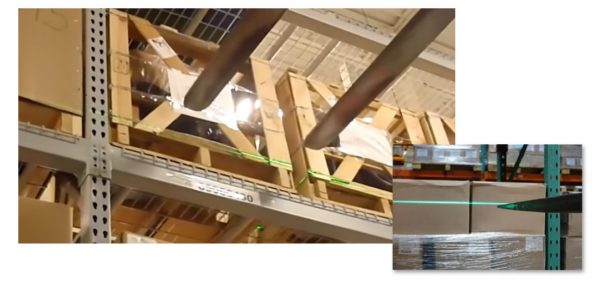

The video below helps illustrate how the camera view can help the driver see the left and right-hand forks clearly on the monitor, which ensures the forks are placed in the pallet openings.

5. Improves Ergonomics

Forklift operators suffer from musculoskeletal and repetitive use injuries for a variety of reasons, including lengthy stretches of sitting, bending into uncomfortable positions, and spending the day riding in a machine with no suspension.

Absenteeism and workers’ compensation lawsuits are often caused by lower back pain, musculoskeletal injuries, and chronic strain injuries.

The ergonomically-positioned monitor helps relieve neck strain and eliminates bad neck posture, allowing drivers to look at the road at a comfortable, natural viewing angle.

By looking at the image on the display, the driver has a direct view of the fork. This improves your work capacity and your efficiency by reducing your nausea and also assists you in making your muscles less strained.

6. Assist with Placing and Retrieving High Loads

A forklift camera would be especially useful in warehousing and storage operations where goods are kept high on racks.

The camera can be installed at fork level to assist your forklift operators in directing the tines of the forklift into the pallet pockets.

Reduce the likelihood of pallets being pushed off racking, products being lost due to uneven lifting/fork positioning, or products being harmed as a result of the forks coming into contact with them. It can also be very useful for reading labels.

7. Help with More Accurate Picking

Newest laser alignment and camera system used in forklifts use lighting technology and also camera images to assist forklift operators in precisely guiding those pointy forks where they want them to go.

The Forklift laser alignment system visually assists Forklift operators as they guide forks to the desired height by utilizing an integrated laser.

-

When visibility is poor, the laser alignment system provides guidance to the Forklift operator. The powerful but safe beams can be activated automatically or manually when the Forklift moves.

-

Because laser beams do not sag or bend with gravity, they are precise and accurate for Forklift alignment.

-

The Forklift laser alignment system saves businesses time and money by reducing the occurrence of accidents and damage to goods while in operation.

-

Combining the benefits of laser and camera vision in one device ensures fork alignment. They all work together to prevent damage when picking up pallets and accurately placing them in racks.

Kocchi’s Laser & Camera Combo System

Final Thoughts

Forklift truck accidents are bad for everyone involved, including the operator, your business, and your fleets. Having the proper equipment on your forklift trucks will drastically reduce the chances of being involved in an accident.

As a result, it’s important that your operator and trucks have all of the necessary tools to operate in the safest possible environment.

Any questions or benefits we’ve missed out? Let us know by leaving your message.

Talk to one of our helpful customer service representatives to learn more about Kocchi’s forklift camera system solution for your organization / resell business as a safety measure for forklift operators.

Leave A Comment