Project Description

RadarCam® Radar Obstacle Detection Camera for Commercial Vehicles and Machines

Operators of heavy machinery in mining, quarrying, agriculture, and construction face significant risks that necessitate rigorous safety protocols. Limited visibility is a primary concern: blind spots on this equipment are vast, extending beyond the rear and sides to include the front view, particularly from raised operator seats.

Compounding the issue, harsh terrains, extreme weather, dense dust, and low-light conditions frequently combine to further obstruct the operator’s field of vision.

Video and Radar-based Vehicle Collision Avoidance Solution

RadarCam® 24GHz Radar & Camera Blind Spot Detection System

Drivers are given an active warning with this active detection system to make your trucks and mining machines even safer.

Combining the benefits of radar and camera in one device for mining applications, Kocchi’s radar camera system allows drivers to assess the situation at a glance using the monitor.

Why RadarCam® System?

Today’s commercial, construction and agricultural vehicles rely on radar systems to improve their safety. Whatever industry you work in you will be reliant on some type of vehicle, and daily operations and tasks can include a diverse range of environments and spaces.

Camera and monitor systems provide drivers with an invaluable visual aid to the surroundings of the vehicle. However, in difficult conditions, a range of complementary devices are vital to give visual and audible operator warnings.

Whilst radar sensors offer a form of detection, RadarCam® radar system has been designed to detect hazards within a vehicle’s blind spot and combined with camera images, significantly reducing accidents by alerting the operator whose attention cannot be focused on all hazard areas.

Gives Your Drivers an Active Warning

The Long-Range Detection (LRD) 24GHz Millimeter-Wave sensors identify objects and persons in the vehicle’s close area, warning drivers with both visual and audio alerts. The alert sound and the graphic indications on the monitor would warn the driver.

-

Integrates with camera and monitors to provide both visual and audible alerts

-

This radar detection kit includes a 720P camera (810) and a HD 7″ monitor

-

Customize your detection zone and range!

-

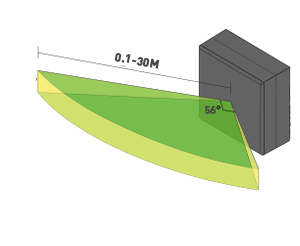

Supports detection zone up to 30M

-

Uses advanced 24GHz Microwave Radar

-

Can be upgraded to 77GHz Microwave Radar

-

Audible alert increases as an object gets closer, automatically going to solid and constant tone when an object is in the red zone

-

Includes specialty brackets that allow more flexibility in mounting

Accurate Detection of People and Objects

The RadarCam® radar system uses millimeter wave technology to transmit millimeter waves and receive the reflected signal from the target. After calculation, the relative distance, speed, angle, and direction of movement between the car body and other objects can be quickly and accurately obtained.

Mud splash, rain, snow, unexpected temperature fluctuations, or falling leaves have no effect on the identification process, which means drivers can do their duties more quickly and effectively.

Smart Alerts with Camera Vision and Radar

It combines radar signals and camera images. In addition to the acoustic signals and camera pictures, the display has an overlay that keeps flashing quickly to warn the driver.

This configuration guarantees that drivers have a comprehensive vision of their surroundings, giving them the peace of mind that they will be able to work more safely.

Explore

RadarCam® Kit Systems

Machinery Compatible

with the RadarCam® Combination Radar & Camera Detection System

with the RadarCam® Combination Radar & Camera Detection System

Kocchi’s RadarCam® Combination of 24GHz Radar & Camera Detection System can be adapted to all brands and types of industrial and construction machinery: from forklifts to telescopic handlers, excavators and loaders.

Bulldozers

Container forklifts

Front-loading forklifts

Loaders

Reach trucks

Concrete mixers

Mini loaders

Rigid dump trucks

Tracked excavators

Wheel excavators

More information

Enhance safety with Kocchi’s camera monitor system. Contact us for more information about the active system RadarCam. Or check our Dealer Page to join our dealers network.

Discuss your next project with us

Do you have a project or installation? Whether you are looking for standard camera system to suit your needs, or specialized radar camera system to solve unique challenges, we can help.

We’re always happy to talk through your ideas and requirements. Ready to talk about your next project with us?

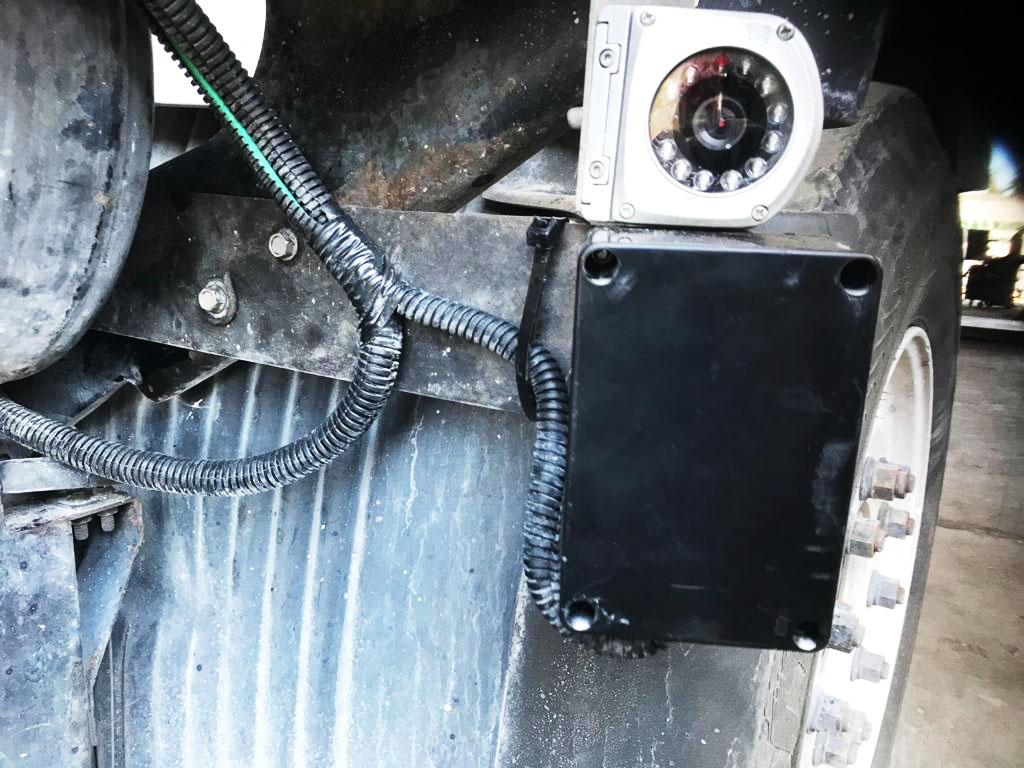

INSTALLATION GALLERY

RadarCam® Frequently Asked Questions

Blind-spot monitoring (BSM) is an advanced safety feature that alerts drivers when there is a vehicle in a car’s blindspot. BSM is standard in many new car models, although some automakers offer it only as an additional feature sold as a part of a package for an extra cost.

Some manufacturers use different names for BSM — like blind-spot detection, blind-spot information system and others. Even if it’s called something different, the systems all perform the same safety function of alerting drivers to objects in blind spots.

Radar is a radio-wave-based object detecting technology. The following are some of the advantages of radar:

-

Outdoor use that is dependable. Radar sensors are impervious to wind, rain, snow, fog, and sunshine. They are less sensitive to temperature variations and can work in a wider temperature range than other technologies.

-

Its long sensing range allows for versatile installation.

-

They’re more durable and need less downtime.

Kocchi’s provides two radar frequencies: 24 GHz and 77 GHz. The 24 GHz has a larger range and is more resistant to environmental factors, but it has significantly coarser precision. The 77 GHz offers superior accuracy, can see a broader range of targets and is weather resistant.

Radar sensors and camera images are an excellent choice for applications requiring the detection of a vehicle or the avoidance of a collision when moving equipment. Radar, for example, can be used for:

-

Vehicle detection in traffic and parking applications, toll booths, loading docks, drive-thrus, shipping canals, and railroads (including automobiles, trucks, and trains).

-

Avoiding collisions in ports and manufacturing (i.e. overhead and gantry cranes)

-

On-board mobile equipment collision prevention (i.e., reach stackers, forklifts, and mining vehicles)

-

Avoiding collisions in low-visibility manufacturing situations (i.e., overhead bridge cranes)

-

Level measurement through steam or dust, where ultrasonic may struggle

-

Provide consistent position input (i.e., reach stackers or ground support equipment like baggage handlers or de-icing vehicles)

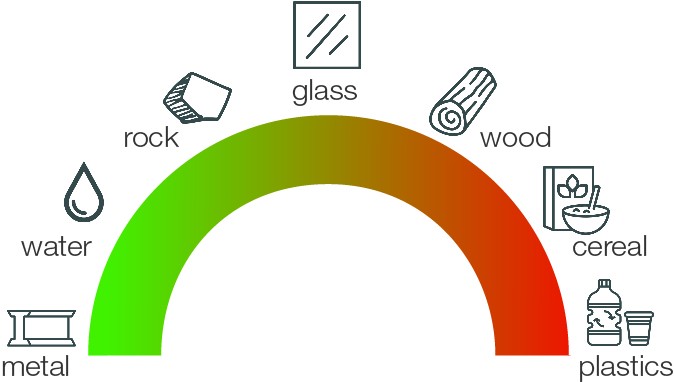

The things that a radar sensor can detect are determined by the sensor’s operating frequency and the material’s dialectric constant.

Lower frequency sensors (24 GHz) need a greater dialectric constant, such as metal or huge quantities of water. Higher frequency sensors (77GHz) can see a lot more, including non-ferrous objects like glass, wood, and other organic materials.